Sports Goods

Pickleball Paddle

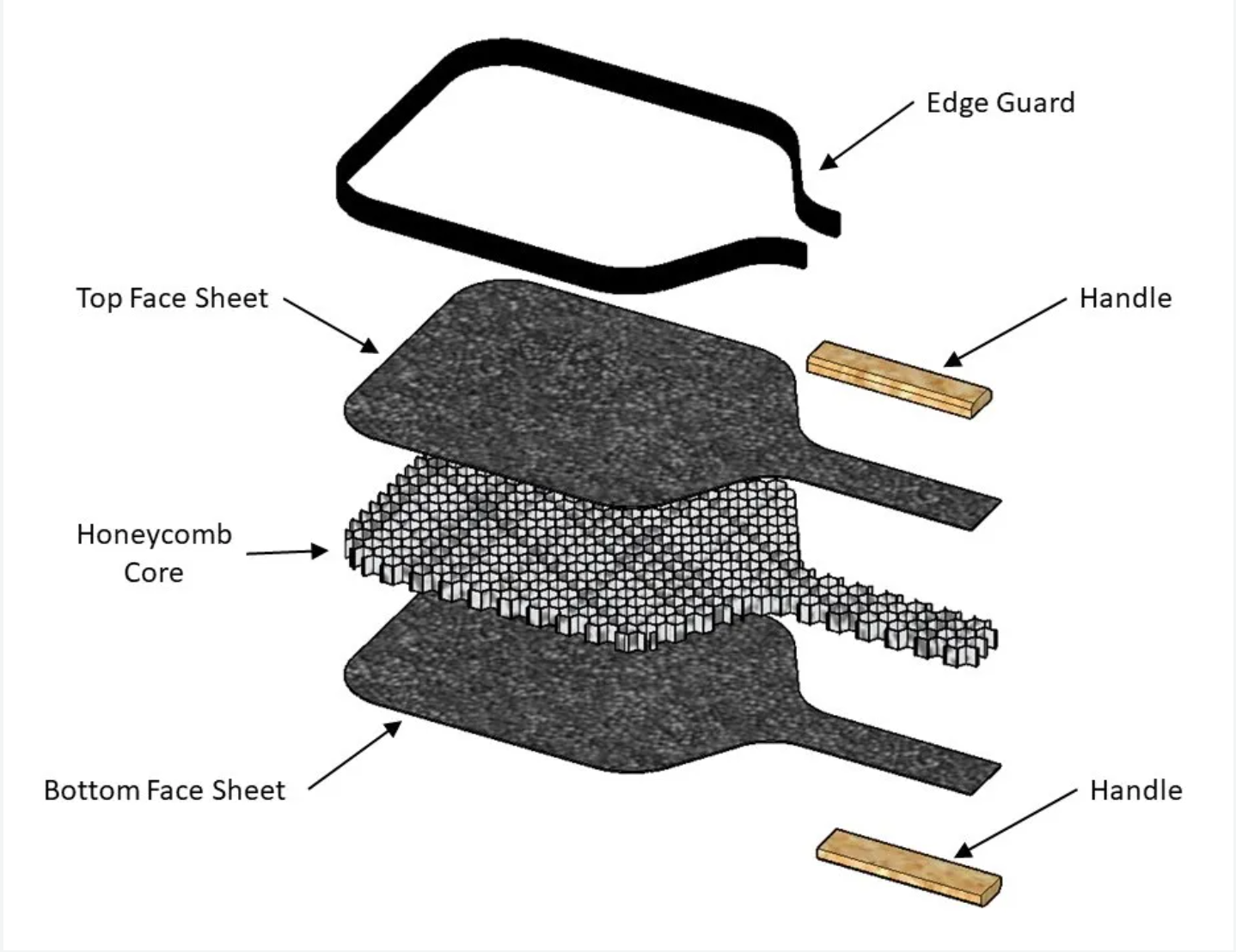

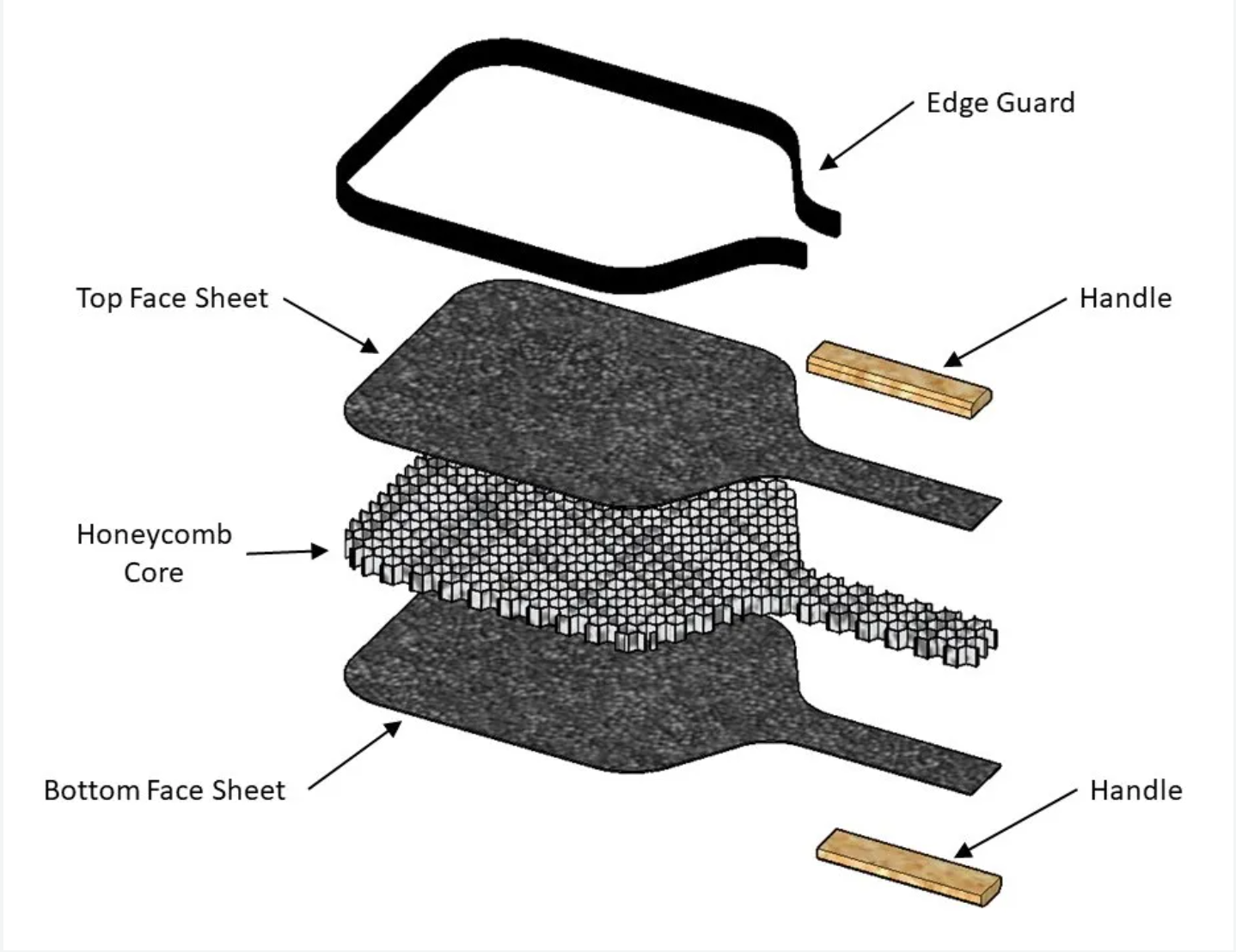

Modern paddles are composite sandwiches, meaning they are built from multiple layers, each with a specific function. Polypropylene Honeycomb is the gold standard and most common core material. It's a plastic honeycomb structure that offers an excellent balance of power, control, and quietness. It's also very durable. Fiberglass (Composite)is the smooth, hard surface that makes contact with the ball. The material here greatly affects spin, durability, and feel. It is Very common and popular. Fiberglass faces are more flexible than carbon fiber. This flexibility creates a "trampoline effect" which generates more power. The texture on fiberglass also aids spin.

Pickleball Panel

The application of high-performance composite materials in pickleball paddle panels marks a significant advancement in the evolution of sports equipment. These materials offer light weight, strength, responsiveness, and durability, which enhance both the performance and experience of players.These composite panels are typically bonded to a lightweight core, such as a polypropylene honeycomb, forming a sandwich structure that combines strength, stiffness, and low weight. The use of high-performance composites greatly enhances the durability, responsiveness, and consistency of pickleball paddles. For example, fiberglass panels allow more flexibility and spin control. Moreover, these materials are resistant to impact, deformation, and weathering, maintaining reliable performance even after long-term use. This makes them ideal for both professional players and recreational users who demand quality and stability.

Pickleball Practice Board

Thermoset honeycomb sandwich panels are a very good fit for high-performance practice rebounders. A thermoset-faced skin (fiberglass with an epoxy or phenolic resin) bonded to a honeycomb core creates a stiff, thin panel used as the “wall” that a ball rebounds from. Honeycomb sandwich panels can be made in light, flat sections that mount into a wheeled frame or are fence-mounted for indoor/outdoor installation. This enables larger, transportable rebounders with consistent bounce across the whole face. By changing core cell size, panel thickness, or skin layup (thermoset resin + fiber type), manufacturers tune stiffness and energy return so the rebound speed/angle matches training goals (slow for dinks, snappy for drives).